Subor offers a comprehensive range of GRP fittings engineered to ensure full integration with our GRP pipe systems, delivering unmatched reliability, hydraulic performance and structural continuity across the entire pipeline network.

Manufactured with the same advanced technology and quality standards as our pipes, Subor GRP fittings are designed to withstand the same pressure, environmental and operational conditions, providing consistency across all components of a project.

Our standard fitting portfolio includes:

Elbow

Concentric Tee

Tangential Tee

Concentric Reducer

Eccentric Reducer

Flange

Blind Flange

Puddle Flange

Wall Coupling

Wye

Marine Lug

Spools

Whether the need is for precise direction changes, transitions or branch connections, Subor’s GRP fittings are tailored to meet the technical demands of your system. In addition to our standard offering, we provide custom-engineered fittings to suit unique geometries and installation constraints.

Our standard fitting portfolio includes:

Elbow

Concentric Tee

Tangential Tee

Concentric Reducer

Eccentric Reducer

Flange

Blind Flange

Puddle Flange

Wall Coupling

Wye

Marine Lug

Spools

Whether the need is for precise direction changes, transitions or branch connections, Subor’s GRP fittings are tailored to meet the technical demands of your system. In addition to our standard offering, we provide custom-engineered fittings to suit unique geometries and installation constraints.

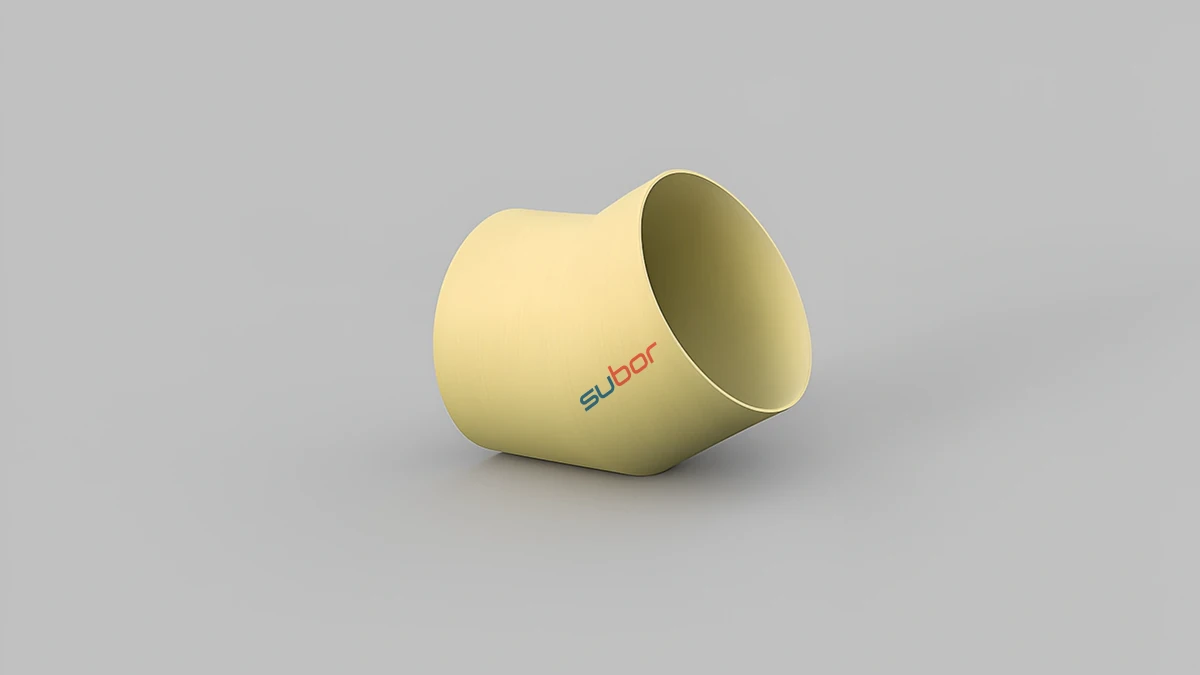

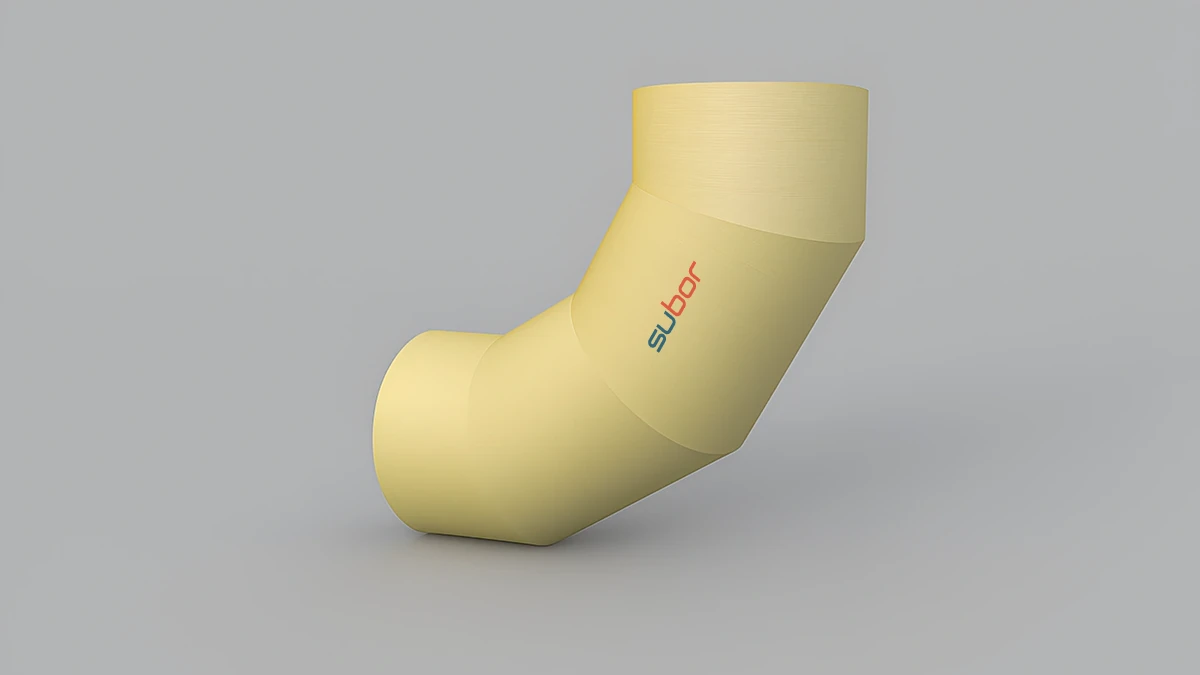

Elbow

Subor Elbows are precision-engineered fittings used to change the direction of the pipeline while maintaining optimal flow performance and structural continuity.

Designed to integrate seamlessly with our GRP pipe systems, elbows are available in all diameters up to DN4000 and a full range of angles to suit various layout requirements and site constraints.

We offer elbows with angles from 0° to 90°, produced using a mitered construction method for maximum durability, hydraulic efficiency and ease of installation:

0°–30° - One miter cut

31°–60° - Two miter cuts

61°–90° - Three miter cuts

Whether for water transmission, industrial networks, or wastewater systems, Subor’s elbows deliver precise directional control with the same high performance and long service life as our GRP pipes.

Designed to integrate seamlessly with our GRP pipe systems, elbows are available in all diameters up to DN4000 and a full range of angles to suit various layout requirements and site constraints.

We offer elbows with angles from 0° to 90°, produced using a mitered construction method for maximum durability, hydraulic efficiency and ease of installation:

0°–30° - One miter cut

31°–60° - Two miter cuts

61°–90° - Three miter cuts

Whether for water transmission, industrial networks, or wastewater systems, Subor’s elbows deliver precise directional control with the same high performance and long service life as our GRP pipes.

Concentric and Tangential Tee

Subor Concentric and Tangential Tees are essential fittings designed for branching pipeline systems or connecting electromechanical equipment such as pumps, flow meters and valves.

Concentric Tees allow for a centrally aligned outlet, ideal for equal-flow division or equipment integration in symmetrical layouts.

Tangential Tees provide an offset outlet, enabling more controlled hydraulic transitions, often preferred in systems where flow direction or turbulence must be minimized.

Both types of tees can be produced with flanged ends to facilitate direct connection to electromechanical components, allowing for easy installation, maintenance and equipment replacement.

Engineered with precision and fabricated to match the mechanical properties of the GRP pipeline system, Subor tees ensure structural continuity, leak-free performance and customizable geometry to suit project-specific layouts.

Whether used to divide flow, connect instruments or integrate with plant systems, Subor’s tee fittings offer the reliability and adaptability needed for high-performance infrastructure.

Concentric Tees allow for a centrally aligned outlet, ideal for equal-flow division or equipment integration in symmetrical layouts.

Tangential Tees provide an offset outlet, enabling more controlled hydraulic transitions, often preferred in systems where flow direction or turbulence must be minimized.

Both types of tees can be produced with flanged ends to facilitate direct connection to electromechanical components, allowing for easy installation, maintenance and equipment replacement.

Engineered with precision and fabricated to match the mechanical properties of the GRP pipeline system, Subor tees ensure structural continuity, leak-free performance and customizable geometry to suit project-specific layouts.

Whether used to divide flow, connect instruments or integrate with plant systems, Subor’s tee fittings offer the reliability and adaptability needed for high-performance infrastructure.

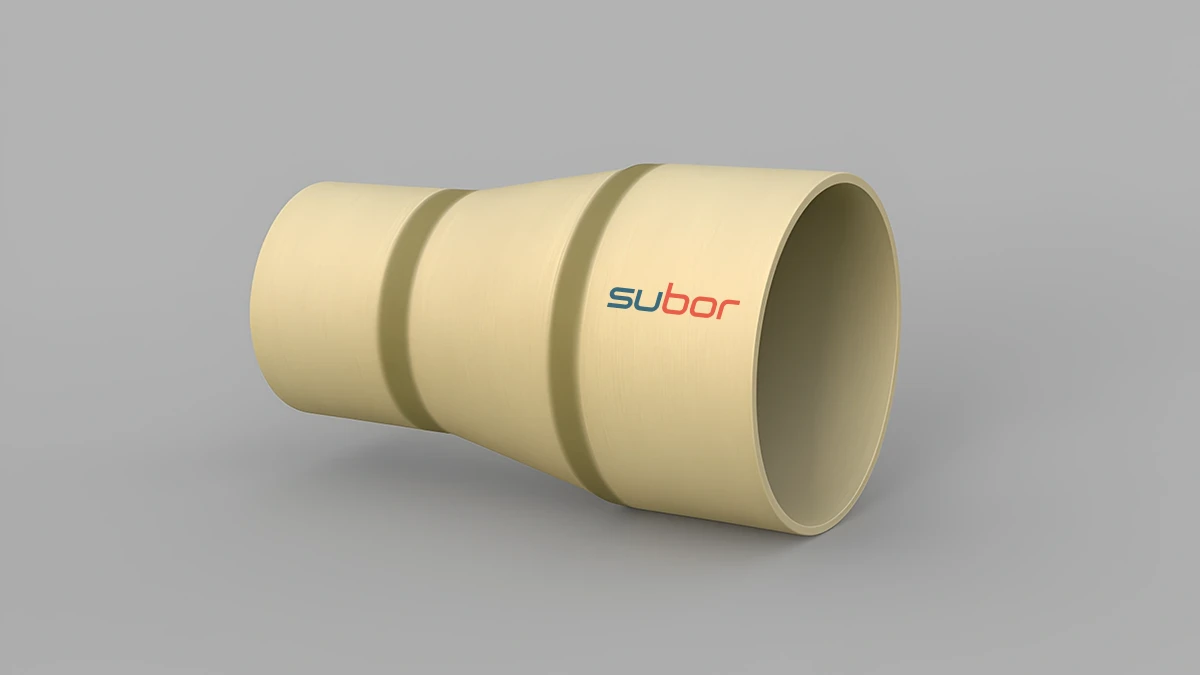

Reducer

Subor Concentric and Eccentric Reducers are used to transition between different pipe diameters within a GRP pipeline system whether to manage flow velocity, pressure dynamics or to integrate with downstream components.

Concentric Reducers offer a symmetrical transition, maintaining a consistent centerline, ideal for vertical installations or flow paths where alignment must be preserved.

Eccentric Reducers provide an offset transition, preventing air entrapment and ensuring smooth flow in horizontal layouts, especially in gravity or partially full systems.

To facilitate integration with different piping systems, Subor can manufacture reducers with flanged ends, enabling direct, secure connections to HDPE, steel, ductile iron, or other pipe materials for compatibility across multi-material networks.

Produced with precision and matched to the hydraulic and mechanical requirements of the system, Subor reducers offer leak-tight performance, structural integrity and customization to project-specific configurations.

Concentric Reducers offer a symmetrical transition, maintaining a consistent centerline, ideal for vertical installations or flow paths where alignment must be preserved.

Eccentric Reducers provide an offset transition, preventing air entrapment and ensuring smooth flow in horizontal layouts, especially in gravity or partially full systems.

To facilitate integration with different piping systems, Subor can manufacture reducers with flanged ends, enabling direct, secure connections to HDPE, steel, ductile iron, or other pipe materials for compatibility across multi-material networks.

Produced with precision and matched to the hydraulic and mechanical requirements of the system, Subor reducers offer leak-tight performance, structural integrity and customization to project-specific configurations.

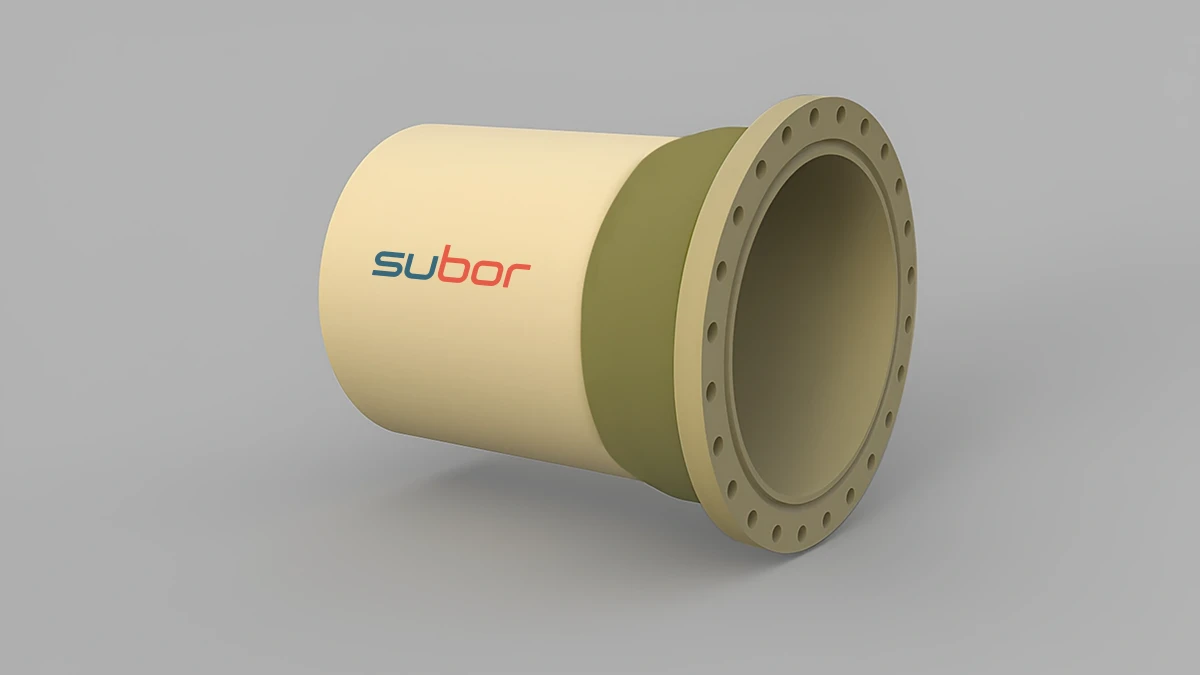

Flange

Subor Flanges are designed to provide reliable, watertight connections between pipeline sections or to integrate GRP pipelines with other piping systems and electromechanical components.

Manufactured according to project-specific requirements, our flanges can be drilled in accordance with international standards, including EN and other globally recognized norms, ensuring full compatibility with HDPE, steel, ductile iron and a wide range of system components.

For effective sealing, Subor flanges can be provided with two gasket solutions:

- O-ring gaskets

- Flat face gaskets

Each flange is engineered for dimensional accuracy, structural strength and corrosion resistance for dependable performance across pressure and non-pressure applications.

Manufactured according to project-specific requirements, our flanges can be drilled in accordance with international standards, including EN and other globally recognized norms, ensuring full compatibility with HDPE, steel, ductile iron and a wide range of system components.

For effective sealing, Subor flanges can be provided with two gasket solutions:

- O-ring gaskets

- Flat face gaskets

Each flange is engineered for dimensional accuracy, structural strength and corrosion resistance for dependable performance across pressure and non-pressure applications.

Blind Flange

Subor Blind Flanges are used to seal off the end of a flanged pipeline for a secure and watertight closure point.

They are ideal for line terminations, future extensions or pressure testing where disassembly may be required later.

Manufactured to the same high standards as our flanges, Subor Blind Flanges are custom-drilled according to international standards and designed to have full compatibility and sealing performance when used with O-ring or flat face gaskets.

They are ideal for line terminations, future extensions or pressure testing where disassembly may be required later.

Manufactured to the same high standards as our flanges, Subor Blind Flanges are custom-drilled according to international standards and designed to have full compatibility and sealing performance when used with O-ring or flat face gaskets.

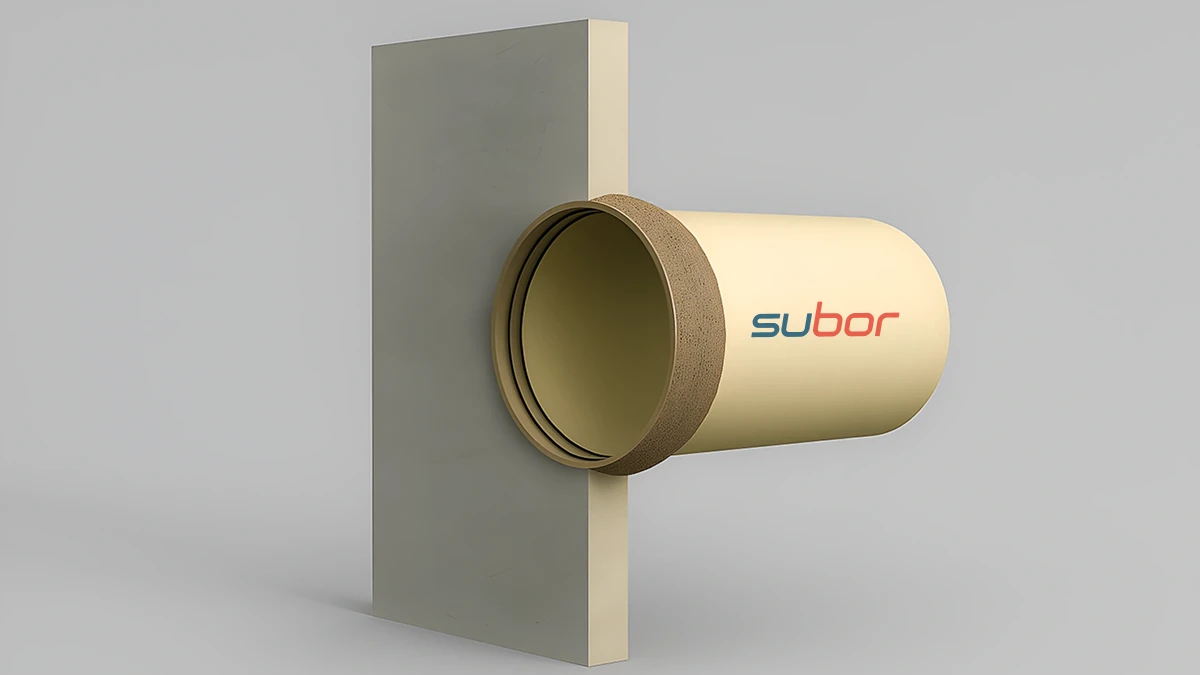

Puddle Flange

Subor Puddle Flanges are engineered to provide a watertight, structurally integrated transition where pipelines pass through concrete walls, making them an essential component in underground and water-retaining structures.

Commonly used in basements, shafts, tanks, reservoirs, and pump stations, these fittings are designed to create a strong mechanical bond with the surrounding concrete for both sealing integrity and structural continuity.

Subor Puddle Flanges are manufactured to resist hydrostatic pressure and environmental exposure, allowing long-term performance and leak protection in the most critical installation zones.

Commonly used in basements, shafts, tanks, reservoirs, and pump stations, these fittings are designed to create a strong mechanical bond with the surrounding concrete for both sealing integrity and structural continuity.

Subor Puddle Flanges are manufactured to resist hydrostatic pressure and environmental exposure, allowing long-term performance and leak protection in the most critical installation zones.

Wall Coupling

Subor Wall Couplings are engineered to create secure and structurally reliable transitions between GRP pipes and concrete walls. Designed for underground infrastructure, tanks, shafts and pump stations, each coupling features an aggregate-coated exterior to maximize mechanical bonding with concrete.

With multiple configurations tailored to space constraints, structural requirements and project-specific conditions, Subor Wall Couplings provide sealing integrity, installation efficiency and long-term performance in both standard and complex scenarios.

With multiple configurations tailored to space constraints, structural requirements and project-specific conditions, Subor Wall Couplings provide sealing integrity, installation efficiency and long-term performance in both standard and complex scenarios.

Wye

Subor Wye Pieces are specialized fittings used to create angled branch connections from the main pipeline offering a gradual transition compared with standard tees, which helps to minimize turbulence and improve hydraulic flow characteristics.

Wye fittings are ideal for gravity flow, irrigation and low-pressure municipal applications.

To improve cross-system compatibility, Subor can also produce Wye pieces with PVC outlets for seamless connection to existing PVC pipelines.

Each Wye is tailor-made to match the main pipe diameter and branch angle, ensuring a secure, leak-tight fit and long-term structural reliability within the GRP system.

Wye fittings are ideal for gravity flow, irrigation and low-pressure municipal applications.

To improve cross-system compatibility, Subor can also produce Wye pieces with PVC outlets for seamless connection to existing PVC pipelines.

Each Wye is tailor-made to match the main pipe diameter and branch angle, ensuring a secure, leak-tight fit and long-term structural reliability within the GRP system.

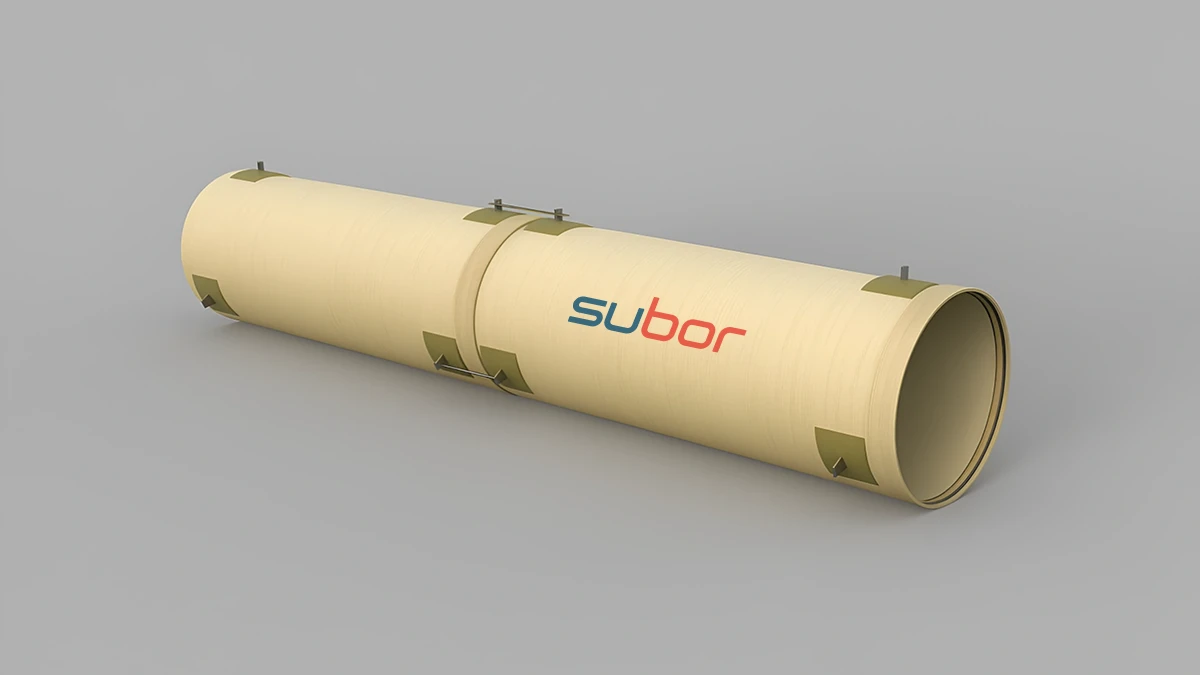

Marine Lug

Subor Marine Lugs are specialized components designed for underwater pipeline installations, where secure handling, controlled submersion and stable positioning are critical.

Integrated into the GRP pipe system, Marine Lugs provide anchorage points for lifting equipment, buoyancy control systems and guide lines, which enables safe and precise placement during marine or subaqueous installations.

These fittings are essential in coastal crossings, submerged intake/outlet lines, reservoirs and offshore infrastructure, assisting pipes to remain aligned and protected during lowering, anchoring or long-term underwater service.

Integrated into the GRP pipe system, Marine Lugs provide anchorage points for lifting equipment, buoyancy control systems and guide lines, which enables safe and precise placement during marine or subaqueous installations.

These fittings are essential in coastal crossings, submerged intake/outlet lines, reservoirs and offshore infrastructure, assisting pipes to remain aligned and protected during lowering, anchoring or long-term underwater service.

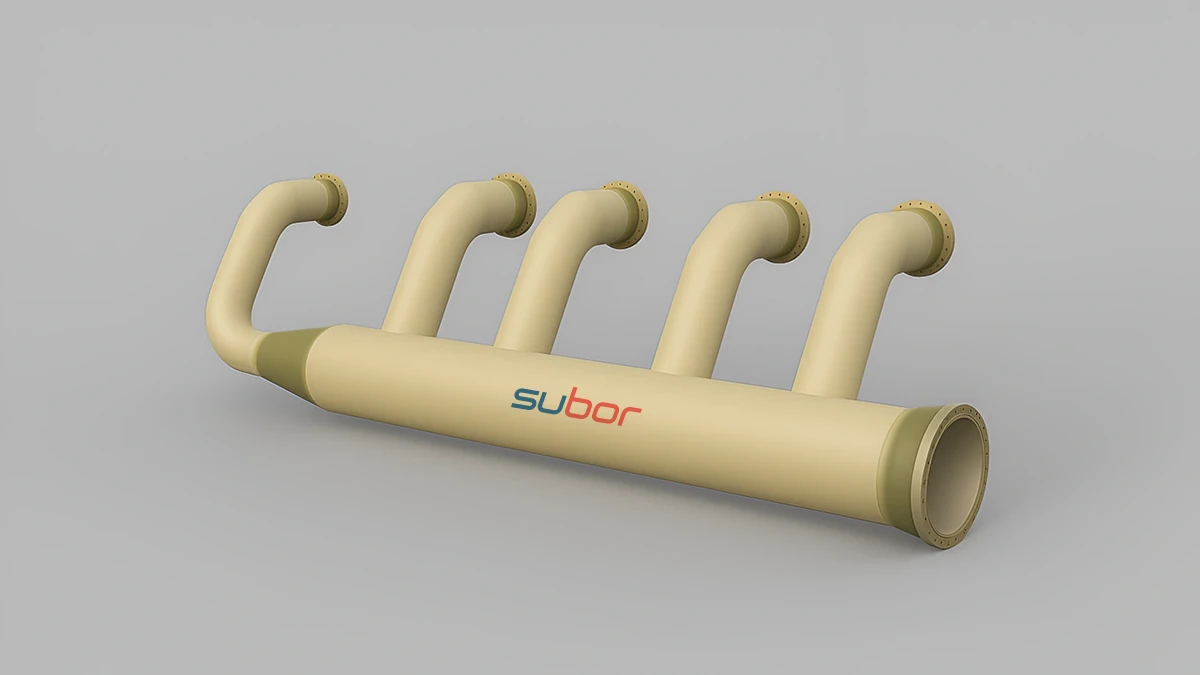

Spools

You shape it. We make it.

Subor GRP Spools are custom-engineered assemblies designed to solve complex geometry and space constraints in pipeline layouts. By integrating various fittings such as elbows, tees and flanges, we provide a precise alternative to standard onsite configurations. Subor engineering team works directly with project’s technical specifications to develop spool drawings that meet all hydraulic and structural requirements for better integration into the wider system.

Since these units are manufactured under controlled factory conditions to the same high standards as our standard GRP products, they offer superior reliability compared to complex field joints. Utilizing spools significantly reduces onsite labor and accelerates installation timelines. When standard fittings are insufficient for project demands, Subor Spools offer a high-performance solution that maintains the integrity of the entire pipeline.

Subor GRP Spools are custom-engineered assemblies designed to solve complex geometry and space constraints in pipeline layouts. By integrating various fittings such as elbows, tees and flanges, we provide a precise alternative to standard onsite configurations. Subor engineering team works directly with project’s technical specifications to develop spool drawings that meet all hydraulic and structural requirements for better integration into the wider system.

Since these units are manufactured under controlled factory conditions to the same high standards as our standard GRP products, they offer superior reliability compared to complex field joints. Utilizing spools significantly reduces onsite labor and accelerates installation timelines. When standard fittings are insufficient for project demands, Subor Spools offer a high-performance solution that maintains the integrity of the entire pipeline.

Need a Customised Solution?

For projects requiring special configurations or performance criteria, our team is ready to assist with tailored pipe solutions.

Contact us to reach our sales team and discuss your project needs.

Contact us to reach our sales team and discuss your project needs.